The innovative laboratory that prepares biological products by processing bird droppings into organic biofertilizers for the purposes of their introduction into crop production, operates under the Kazakh Agrotechnical University named after S. Seifullin and produces up to 5,000 liters of liquid preparations per month. Currently, the new method of processing has been successfully implemented in domestic poultry farms of the Akmola region, in particular in JSC "Akmola-Phoenix" and LLP "KAZGER-KUS", as well as in LLP "ADMInvestment" of the Aktobe region, the World of NAN reports with reference to the press service of the university.

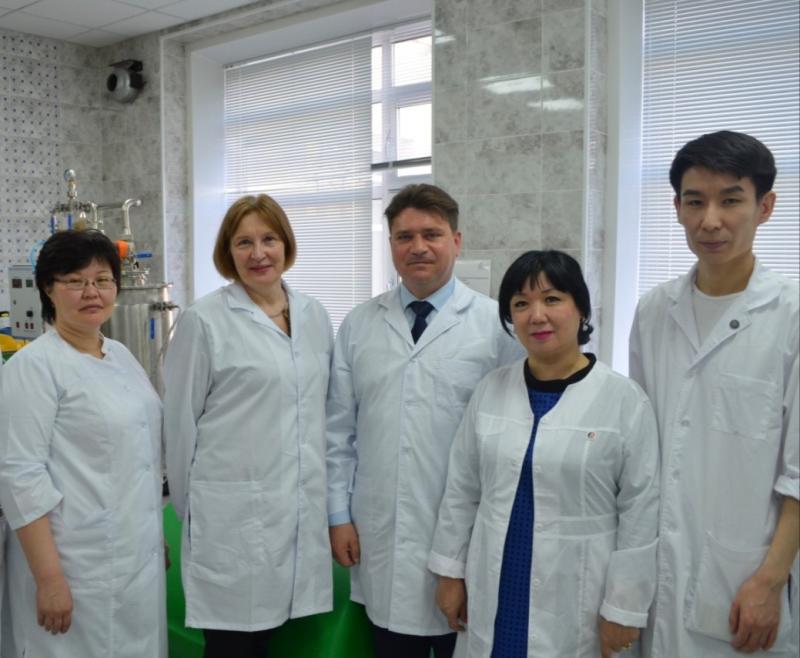

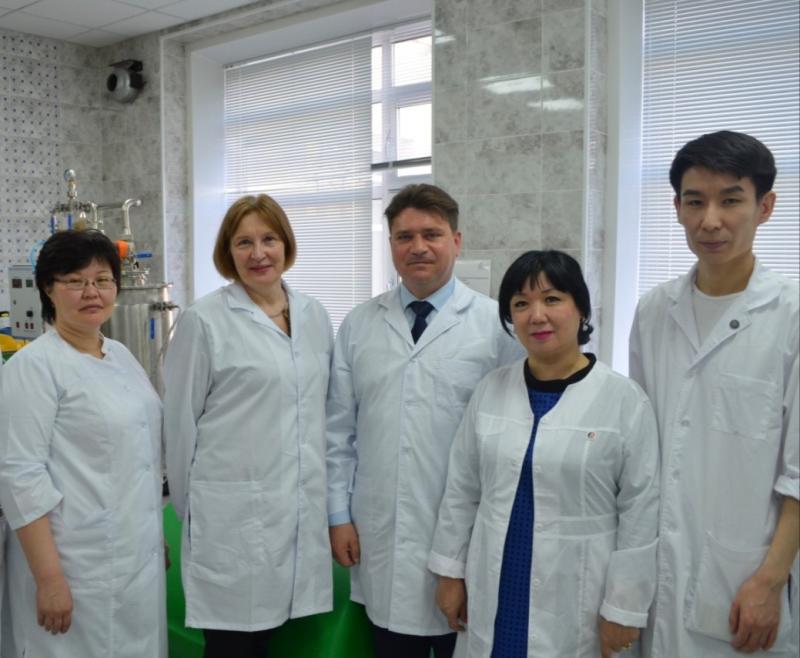

A modern laboratory of microbial biotechnology that produces biological products by processing bird droppings is equipped with all the necessary equipment, including an automatic fermenter for 125 liters and bioreactors, with a total volume of 1,000 liters. This technological line today allows to produce up to 5,000 liters of liquid biological products per month under the trademarks "Agro-MIX", "Compo-MIX" and "Agrarka".

According to the press service, in 2017, Doctor of Biological Sciences, Professor of the Department of Soil Science and Agrochemistry of KazATU named after S. Seifullin A. P. Nauanova won a grant from the World Bank for the commercialization of scientific developments in the field of biotechnological research. Within the framework of the project "Stimulating productive Innovations", a startup company "BIO - KATU" LLP was created. The subproject was launched under the title "Development of technology for processing bird droppings into organic biofertilizer with the help of new domestic biological products and their implementation in crop production".

According to the press service, in 2017, Doctor of Biological Sciences, Professor of the Department of Soil Science and Agrochemistry of KazATU named after S. Seifullin A. P. Nauanova won a grant from the World Bank for the commercialization of scientific developments in the field of biotechnological research. Within the framework of the project "Stimulating productive Innovations", a startup company "BIO - KATU" LLP was created. The subproject was launched under the title "Development of technology for processing bird droppings into organic biofertilizer with the help of new domestic biological products and their implementation in crop production".

It should be noted that "BIO-KATU" LLP develops and implements domestic technologies in the field of biotechnologies in order to solve the issues of utilization and recycling of agricultural, poultry and animal husbandry waste. And the innovative method is a technological process of processing bird droppings into organic fertilizer with the help of biological products created on the basis of highly effective microorganisms.

"We are not surprised that cattle manure is used in agriculture as an organic fertilizer. However, for a long time, bird droppings were ignored as a potential source of useful organic compounds. Many industrial facilities still simply take it to landfills as biowaste, where it can lie for years, releasing gases harmful to the environment. Meanwhile, bird droppings during processing turn into an excellent fertilizer, which has a beneficial effect not only on the soil, but also helps to significantly increase agricultural productivity. For example, in Canada and Germany, the experience of which we studied, farmers who were in favor of processed bird droppings and not chemical fertilizers had their yields increased by several times. That's why we took on this project, because we wanted to prove that bio-waste can help us achieve good results, especially in crop production. "You just need to understand how profitable and environmentally friendly it is", says the author of the project, a researcher at the university Aynash Nauanova.

The press service notes that the laboratory of BIO-KATU LLP has all the basic microbiological equipment necessary at its disposal not only for the production of biological products, but also for conducting research.

"The equipment includes a biological safety box, thermostats for the cultivation of microorganisms, autoclaves, a fume hood, a distiller, a mixing device for the cultivation of mother culture, display cabinets, a freezer, analytical scales, a microscope, bactericidal lamps, a refrigerator for storing finished products of biological products and much more," the press service reports.

Processing of bird droppings is carried out at a landfill area of 4.8 hectares, located on the territory of the poultry farm of JSC "Akmola-Phoenix", which is located in the Tselinograd district of the Akmola region. The process is carried out using the BACKHUS A36 agitating technology of German production and with the addition of bio-preparations "Agro-Mix", "Compo-MIX" and "Agrarka".

Processing of bird droppings is carried out at a landfill area of 4.8 hectares, located on the territory of the poultry farm of JSC "Akmola-Phoenix", which is located in the Tselinograd district of the Akmola region. The process is carried out using the BACKHUS A36 agitating technology of German production and with the addition of bio-preparations "Agro-Mix", "Compo-MIX" and "Agrarka".

"The landfill is equipped with special agricultural and industrial equipment, including a roll baler for picking and pressing hay into rolls, a coarse feed shredder in rolls for adding straw to compost masses, a special agricultural semi-trailer for applying ready-made biofertilizer to the fields. "In addition, a thermometer, a moisture meter and a gas analyzer are used to control the process of composting bird droppings, as well as a tape dispenser for packaging ready-made organic fertilizer for its further implementation," the report states.

As it turned out, KazATU boasts not only innovative developments. According to indicators of 2019, "BIO-KATU" LLP, as per the national business rating of Kazakhstan's best taxpayers in the region and the country was rated 6th (gold) among the enterprises of the Republic of Kazakhstan in nomination of "Contribution to the state budget" in "research and experimental development on biotechnology". In addition, BIO-KATU LLP was awarded the status of "Industry Leader 2020" for its successful and productive activities.

The editors of World of NAN remind you that the video on the work of the laboratory is on our portal. By clicking on this link, you can get acquainted with the work of scientists and see the entire process of preparing biofertilizers for yourself: https://www.youtube.com/watch?v=d6m_5hMCyNw

According to the press service, in 2017, Doctor of Biological Sciences, Professor of the Department of Soil Science and Agrochemistry of KazATU named after S. Seifullin A. P. Nauanova won a grant from the World Bank for the commercialization of scientific developments in the field of biotechnological research. Within the framework of the project "Stimulating productive Innovations", a startup company "BIO - KATU" LLP was created. The subproject was launched under the title "Development of technology for processing bird droppings into organic biofertilizer with the help of new domestic biological products and their implementation in crop production".

According to the press service, in 2017, Doctor of Biological Sciences, Professor of the Department of Soil Science and Agrochemistry of KazATU named after S. Seifullin A. P. Nauanova won a grant from the World Bank for the commercialization of scientific developments in the field of biotechnological research. Within the framework of the project "Stimulating productive Innovations", a startup company "BIO - KATU" LLP was created. The subproject was launched under the title "Development of technology for processing bird droppings into organic biofertilizer with the help of new domestic biological products and their implementation in crop production".

Processing of bird droppings is carried out at a landfill area of 4.8 hectares, located on the territory of the poultry farm of JSC "Akmola-Phoenix", which is located in the Tselinograd district of the Akmola region. The process is carried out using the BACKHUS A36 agitating technology of German production and with the addition of bio-preparations "Agro-Mix", "Compo-MIX" and "Agrarka".

Processing of bird droppings is carried out at a landfill area of 4.8 hectares, located on the territory of the poultry farm of JSC "Akmola-Phoenix", which is located in the Tselinograd district of the Akmola region. The process is carried out using the BACKHUS A36 agitating technology of German production and with the addition of bio-preparations "Agro-Mix", "Compo-MIX" and "Agrarka".

Обсуждение